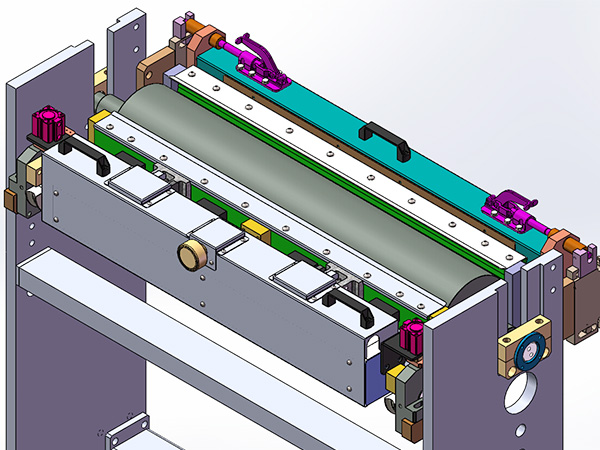

Coater scraper system is a key component of the coater. Its main function is to evenly distribute the coating on the surface to be coated through the scraper and use the pressure between the scraper and the surface to control the thickness of the coating.

The structure of the scraper coater includes a mechanical part and a hydraulic part.

The mechanical part is mainly composed of a rotating scraper, a paint container and a supporting structure. The scraper is usually made of high-quality spring steel or other wear-resistant materials to ensure its wear resistance and service life. The supporting structure is used to maintain the stability of the scraper blade and the correct working angle. The paint container is responsible for storing the paint and delivering the paint to the scraper through a pump.

The hydraulic part controls the pressure and rotation speed of the scraper through the control system to control the thickness and uniformity of the coating. During coating, the scraper will rotate at a certain speed and evenly distribute the paint on the surface to be coated. Due to the pressure between the scraper and the surface, the paint will be evenly coated on the surface to form a uniform coating.

In addition, the scraper system also includes an adjustment device, a scraper suspension device and a guide device. The adjustment device can adjust the working pressure, angle and position of the scraper according to the different characteristics and requirements of the coating material.

The scraper suspension device is used to install and adjust the position and angle of the scraper, while the guide device ensures that the scraper can move along the correct trajectory during the coating process to ensure the accuracy and stability of the coating.

In order to ensure the working efficiency and coating quality of the scraper coater, the scraper system needs to be regularly maintained and serviced.

For example, regularly clean the scraper and coating roller and other parts to remove the accumulated paint; regularly add lubricating oil or grease to ensure the smooth and stable operation of the equipment; regularly check the tightness and damage of the scraper, felt roller, conveyor belt and other parts, and replace the damaged parts in time.

When operating the scraper system of the coating machine, you need to pay attention to safety. You should wear protective equipment before operation and ensure that the air around the machine is circulated. Before starting the equipment, you should clean the dust and stains on the surface of the coating to ensure that the paint can be evenly coated. During the operation, the operator should stand next to the equipment, carefully observe the operation of the equipment, and be familiar with the operation process to avoid adjusting the equipment parameters at will.

Copyright © 2024 Dongguan Baoqi Packaging Machinery Co., Ltd. All rights reserved