4dhcpmingchen

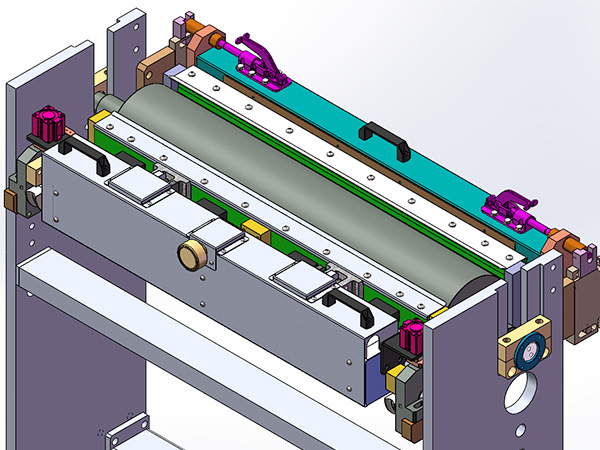

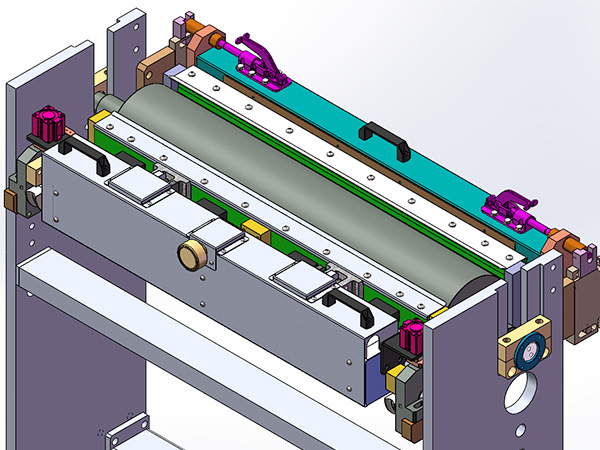

Double scraper system

The double scraper system uses two scrapers to work together, one of which is in contact with the coated substrate or the surface to be scraped, and is responsible for evenly coating the fluid (such as ink, coating, glue, etc.) or material on the substrate, or scraping off excess material on the surface.

The other scraper plays an auxiliary role, such as scraping excess fluid back to the starting point to avoid missed scraping, missed coating or material waste. This design ensures the uniformity and efficiency of coating or scraping.

Advantages and Features

Improve coating quality: The double scraper system can ensure that the fluid forms a uniform coating on the substrate, avoiding problems such as uneven coating thickness and poor appearance quality.

Save materials: By scraping off excess fluid and recycling it for reuse, the double scraper system can significantly reduce material waste and reduce production costs.

Improve production efficiency: The double scraper system has high working efficiency, can quickly complete coating or scraping tasks, and improve the overall efficiency of the production line.

Strong adaptability: The double scraper system can be adjusted and optimized according to different process requirements and is suitable for a variety of materials and coating requirements.